YOKO Pharma

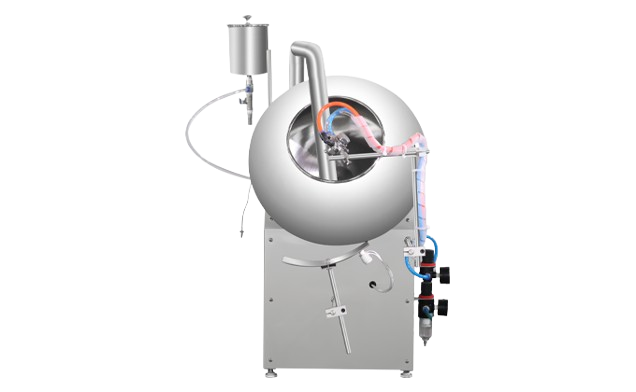

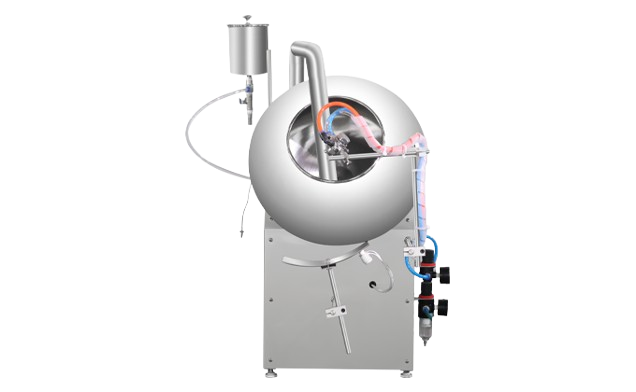

Tablet Coating Machine

YOKO Pharma tablet coating machines are highly automated and engineered to meet the highest standards of safety and quality. As a leading manufacturer of tablet coater systems, we integrate advanced control systems that enable precise regulation of the coating process. These machines can be customized to accommodate various tablet shapes and sizes, enhancing their versatility across pharmaceutical applications.

Our tablet coating machines are designed to minimize waste and significantly reduce contamination risks. Equipped with efficient air handling systems, they effectively remove excess coating solution and prevent the accumulation of dust and contaminants, thereby maintaining a cleaner and more controlled production environment.

AUTOMATIC

YOKO-JB Series

Adopt electric heating blower to do coating, suitable for products that are not fit spraying.

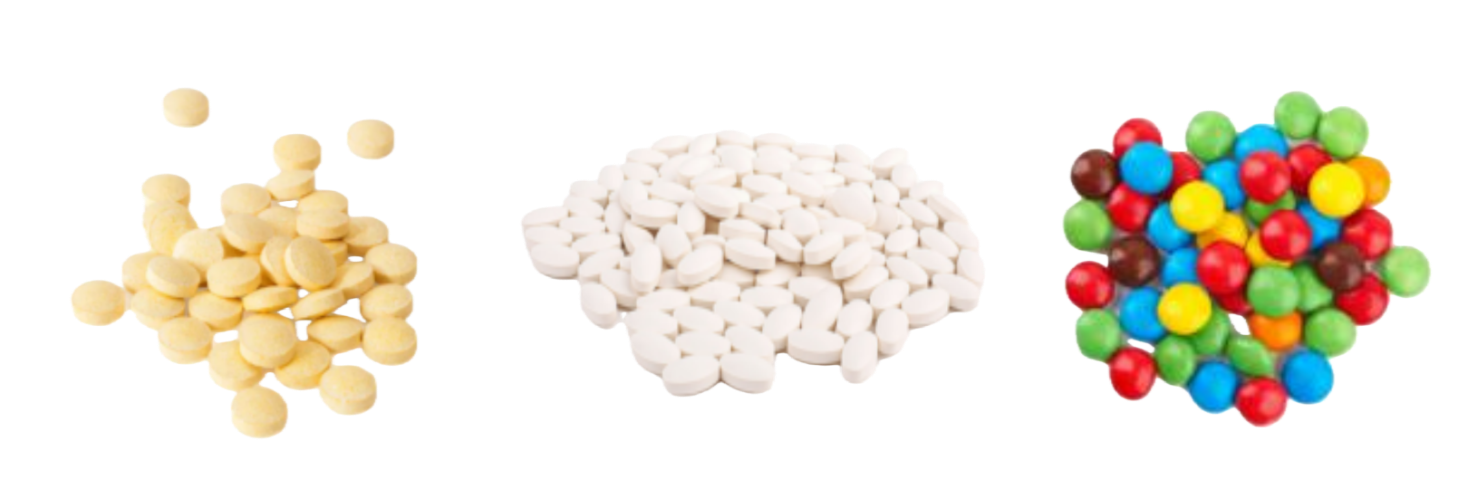

YOKO-JB-E Automatic tablet coater machine is able to coat the outer surface of tablets with a thin layer of coating material such as sugar coating, powder coating, chocolate coating. Forming a strong, dense, complete and smooth surface film on the tablet surface in short time.

FEATURES

- The machine is made of food grade stainless steel, clean and hygienic

- Easy to clean and maintain

- Adopt external heating device, make the temperature even, so that the coating is smoother

- Reasonable design, flexible programming

- Thermal adjustment range is from 30-110℃

- Transmission steady, performance reliable

- Coloring, polishing, drying – 3 in 1

- Individual adjustment switch

- The air outlet pipe extends into the pan to dry the product

TECHNICAL DATA & Benefits

| | | | | | | | |

| | | | | | | | |

Production Capacity (kg/batch) | | | | | | | | |

Regulating Range of Air Temperature (℃) | | | | | | | | |

Speed regulating range of main engine (r/min) | | | | | | | | |

| Custom made according to customer’s request |